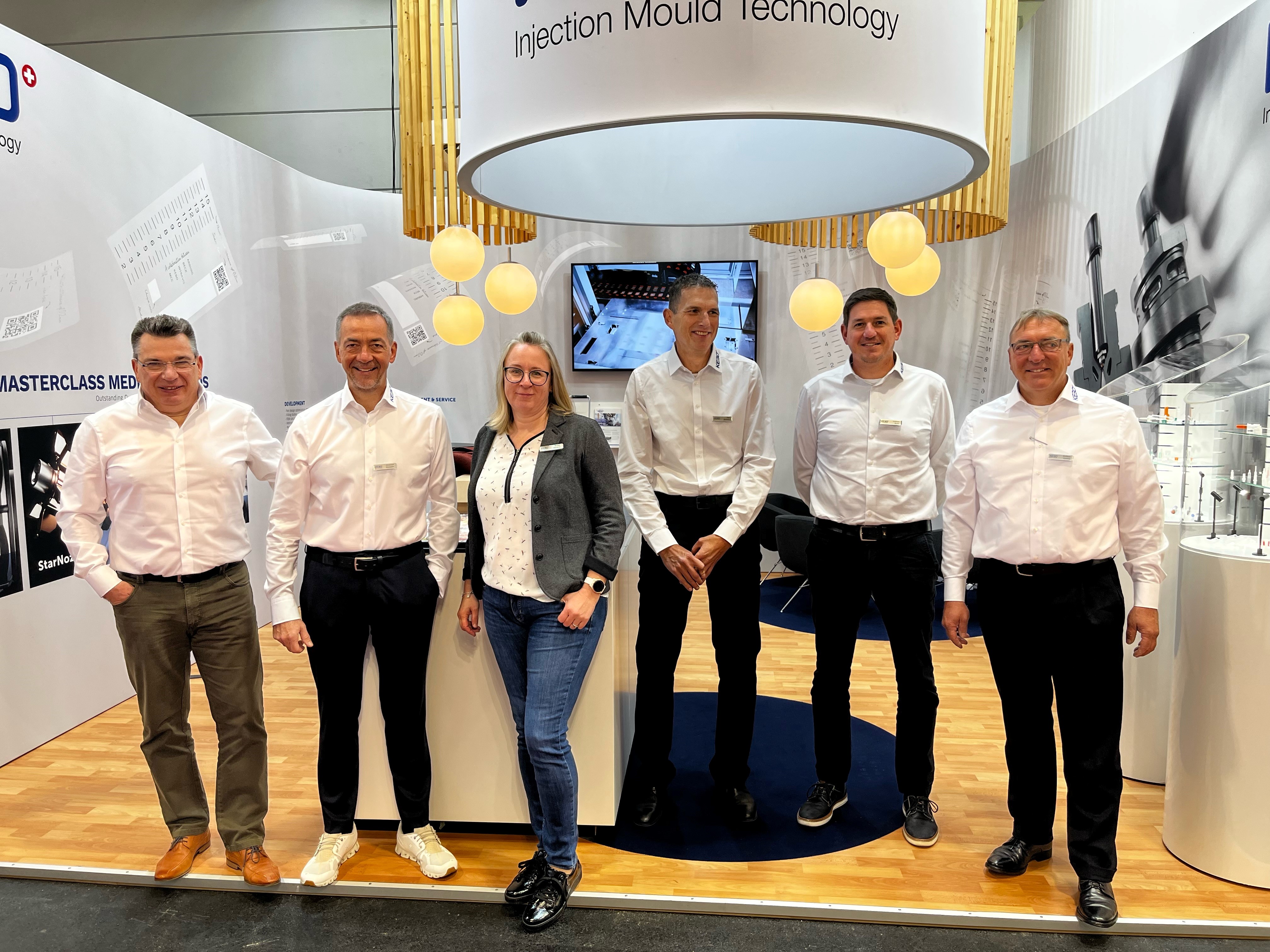

10.2024: Fakuma 2024 - Friedrichshafen DE

FAKUMA is just around the corner and we can hardly wait to welcome you to our stand B3-3313. We have a lot of news!

Medical IML

What has happened? How is the market for IML Medical developing? Thank you very much for the great feedback and valuable input! We have taken your wishes on board and are working as a team ARBURG, Beck Automation, Intravis, KEBO and MCC on the development and realisation of the next IML innovation! Come and visit us - we can ‘lift the curtain a little’ and give you a preview of the upcoming IML Medical 2.0.

KEBO your expert mouldmaker for Diabetes & Obesity

Come and meet us on our KEBO booth B3-3313 to exchange on latest developments for Diabetes & Obesity. The growth in Diabetes and Obesity are one of the global key drivers in the medical and pharmaceutical industry. KEBO is your experienced and reliable partner for high precision mould solutions: whether it's high-volume consumables or complex devices with the highest demands on product quality, we can offer you high-performance hot runner & mould solutions for your requirement.

05.2024: KEBO AT THE NPE 2024 IN ORLANDO WITH IML-MEDICAL EXHIBIT!

The NPE trade fair will take place from 6 to 10 May 2024 in Orlando. The KEBO booth will be located in the South Hall, Level 1, booth no. S30079H (Swiss Pavilion).

Our exhibit at the Arburg booth is expected to be a trade fair highlight. Together with our project partners ARBURG, Inc., Beck Automation AG, INTRAVIS Vision Systems and MCC Label, this development will be demonstrated for the first time outside of Europe!

Further information about this development can be found here:

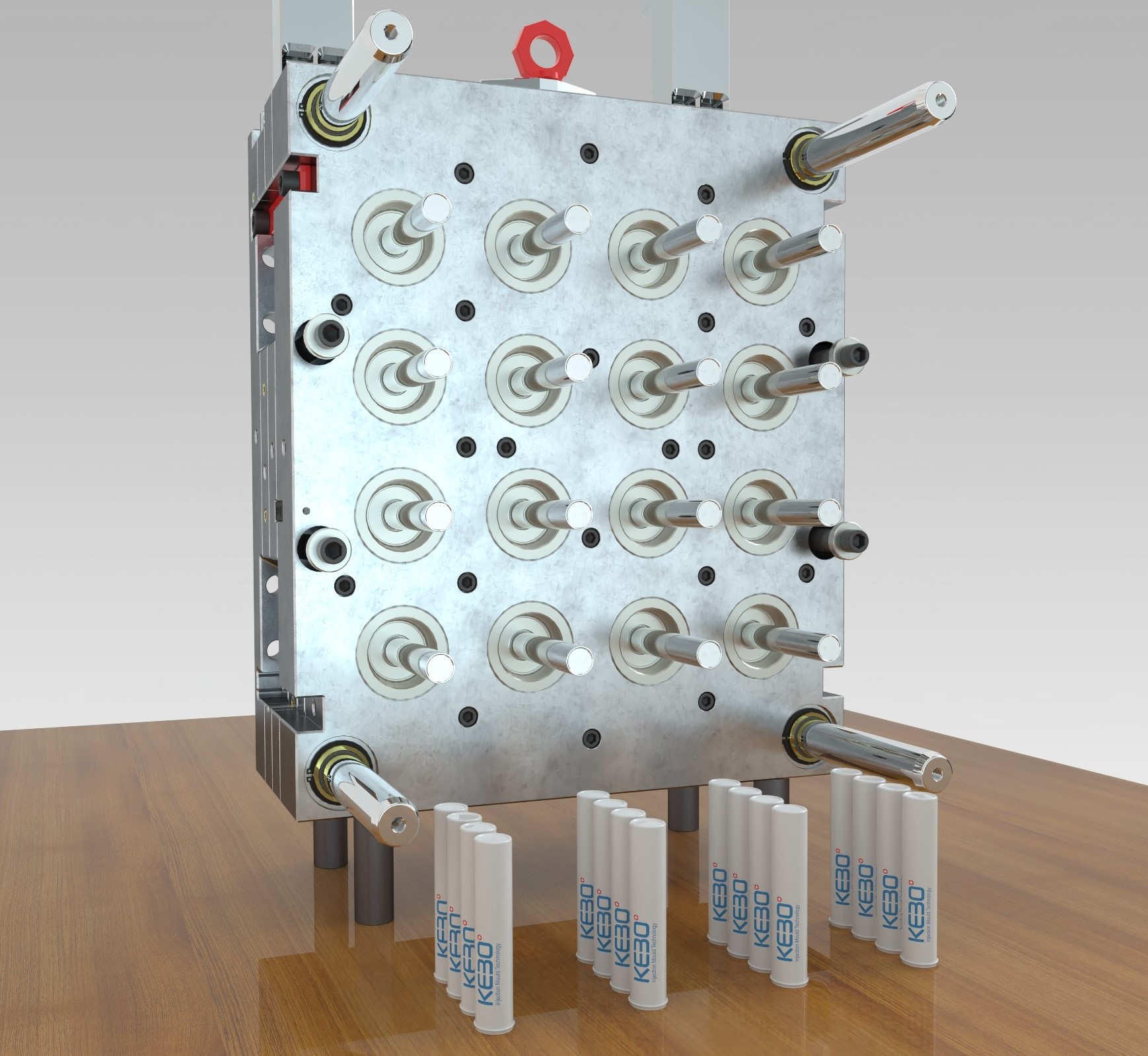

04.2024: KEBO AT THE CHINAPLAS 24 IN SHANGHAI

At the Chinaplas trade fair in Shanghai from 23 to 26 April 2024, a 96-cavity "Needle Cap" tool will be on display at the Sumitomo-Demag stand (Stand C32 in Hall 4.1). The automation will be provided by HAHN Automation Group GmbH.

10.2023: FAKUMA 2023 - erfolgreiche Messe in Friedrichshafen!

KEBO AG has never been so well represented at the FAKUMA trade fair. In addition to its own booth, three KEBO moulds were presented at partner companies:

Engel: 96-cavity mould for a diabetes application

Sepro: 4-cavity cup mould thin-wall

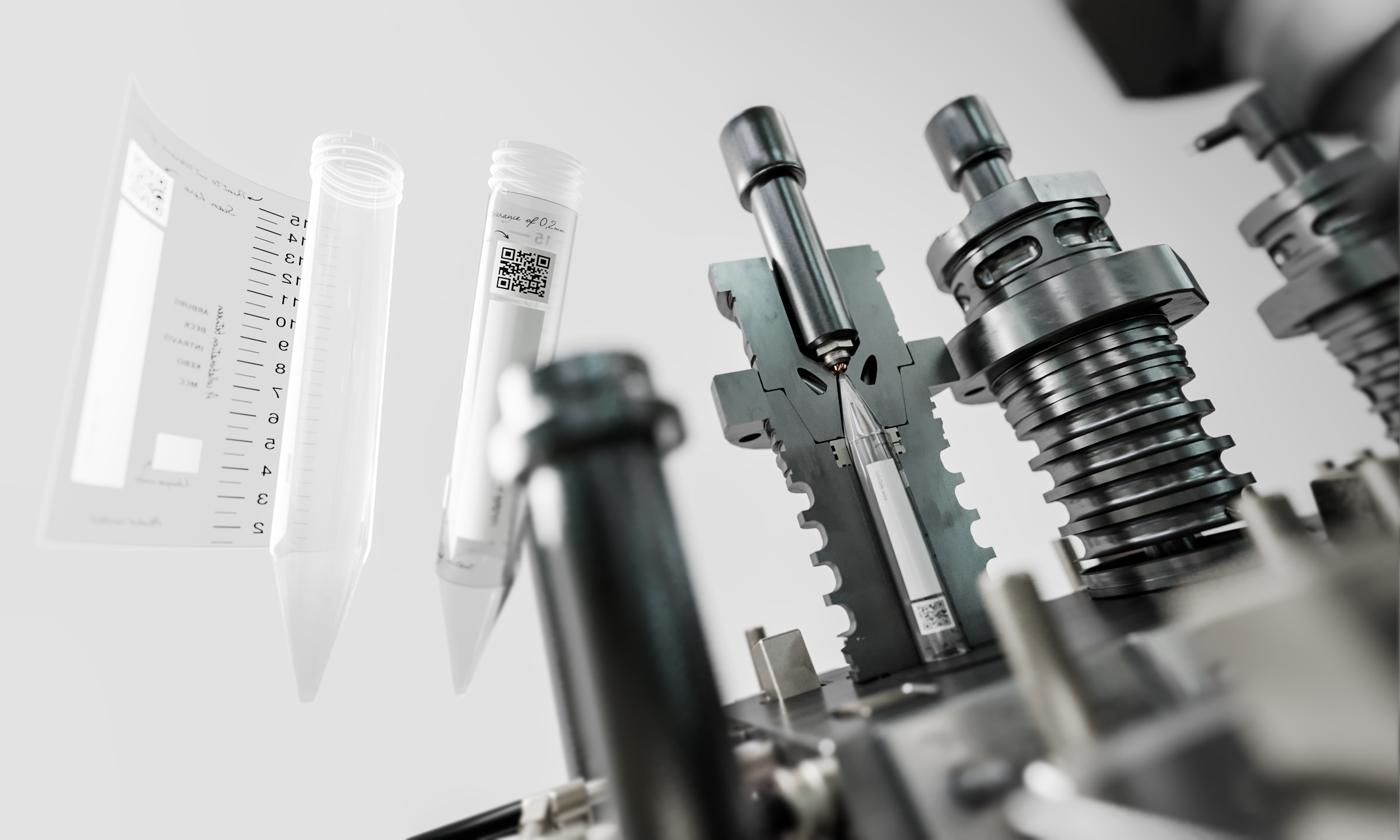

Arburg: 8-cavity mould for centrifuge tubes 15 ml with IML

In particular, the new development "IML-Medical" attracted a lot of attention!

The global medical market is changing: not only rising hygienic demands, but also a reliable traceability, sustainability, and more digitized medical products become vital.

IML opens up new possibilities in the field of medical technology. It guarantees authenticity since the label cannot be removed or replaced. Moreover, the entire supply chain can be easily traced back, ensuring transparency and accountability. By incorporating innovative features like temperature indicators or RFID, IML revolutionizes the way medical products can be monitored, controlled and connected.

More information here:

05.2023: IML GOES MEDICAL - Why In-Mould-Labeling can become a game changer in medical technology

In-Mould-Labeling (IML) is familiar from packaging and is now state-of-the-art. Five partners are developing an IML concept for medical technology. Will this bring about a change in technology?

There is great interest in the new technology on the part of the industry, as additional functions can be integrated into the plastic part. These „add-on functions“ are interesting for the pharmaceutical and medical industry because they open up new potential benefits and markets. The global medical market is changing: new consumer segments are emerging, but also new players (increasingly from the technology sector).

„When it comes to new products, creativity and experience count,“ reports Johannes Strassner, CSO at KEBO. With long-standing partners, the idea was born to jointly develop the topic of IML Medical as a team. Arburg, Beck Automation, Intravis, KEBO and MCC Verstraete worked together on the concept.

10.2022: KEBO change in management as of October 1, 2022

KEBO AG, a manufacturer of high-performance injection molds based in Neuhausen am Rheinfall (Switzerland), has made a change in its management as of October 1, 2022. Long-time CEO and partner, Gerold Keller, who successfully led the company for over 30 years, has handed over the overall management of the company (CEO) to Alexander Anders. Johannes Strassner is now responsible for Sales and Marketing (CSO) and in this function becomes a member of the Executive Board. The two new Board members bring several years of management experience to the company from various positions in mold making as well as injection molding machine industry.

Gerold Keller will remain with the company and will continue to look after selected key accounts. In addition, he will remain on the management board in a supporting role as owner. Finance and Human Resources will continue to be managed by CFO and partner Daniel Bodenmann. Thus, the two shareholder families will remain in the company.

With this personnel change, KEBO AG is taking an important step towards securing the long-term future of the family-run Swiss medium-sized company. "With Alexander Anders and Johannes Strassner, we have been able to attract two personalities with industry and management experience to our company," says Gerold Keller. "This enables us to take in new wind in challenging times and strengthen our position in the market." Daniel Bodenmann adds, "We want to remain independent in the future. A stable ownership structure is important for our employees, customers and partners."

For 43 years, KEBO AG has been consistently and enthusiastically responding to the needs of demanding, international customers. Competence, tradition, high-end technology as well as personal customer support ensure optimal solutions for complex challenges regarding high-performance injection molds with own hot runner technology for medical, pharmaceutical and laboratory applications as well as high-end thin-wall applications.

07.2022: Loyal employees!

Three employees celebrate their company anniversary: 10, 15 and 40 years of service! Our assembly employee Kurt Bai (second from right) was an employee of the first hour in 1979. With a short interruption, he has always worked for KEBO AG! The company founders Charles Bodenmann and Alfons Keller had the right instinct to hire Kurt after he had completed his apprenticeship as a toolmaker! Experience & apprenticeship: that is KEBO's recipe for success, with employees of many years standing and our own innovative training. We are proud of you!

06.2022: KEBO Summer Party

Although the sun did not shine on this day, we were able to enjoy our annual summer party in our application technology center!

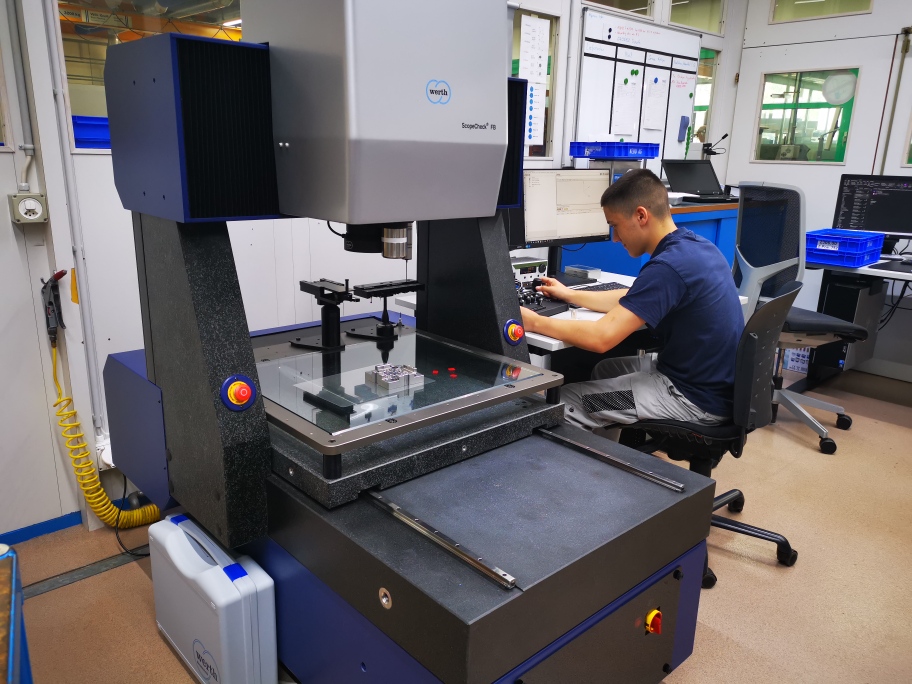

06.2022: New Production Equipment

In order to meet the high demands of our customers, we need not only qualified personnel but also the appropriate equipment. We have supplemented our production equipment in CNC cylindrical grinding and Q-inspection...

11.2021: 20 Years KEBO AG

20 years KEBO work anniversary for our Head of Quality inspection, Andreas Nitz! A BIG thank you to him for his loyalty and for his work commitment!

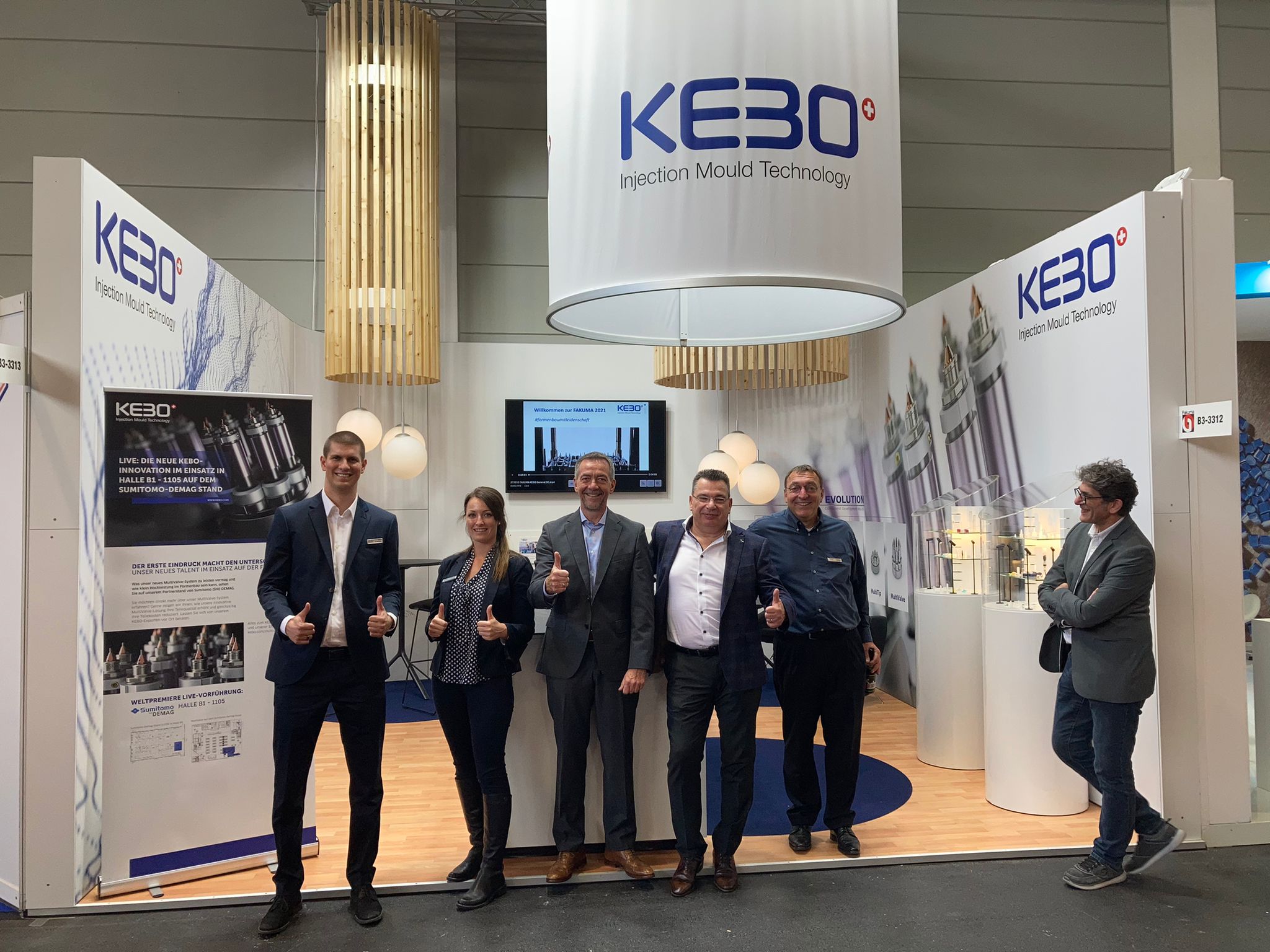

10.2021: FAKUMA 2021 in Friedrichshafen

There's nothing like personal contact... 😊

We had so much fun at FAKUMA show!

KEBO AG presented many pieces of news at Fakuma 2021. Our innovation «MultiValve» met with particularly great interest.

…and we welcome your feedback, that our compact KEBO valve gate system perfectly meets the needs of complex part geometries in the medical market.

Thank you very much for your great interest and the many questions about the use of our new technology.

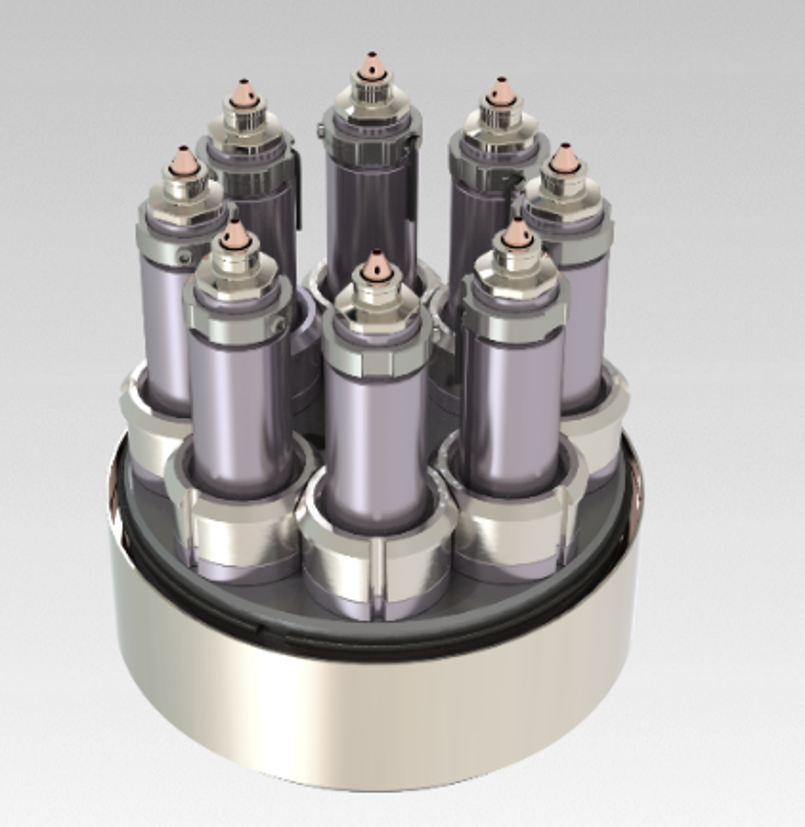

09.2021: New KEBO Hotrunner System!

MultiValve – KEBO‘s new in-house development – combines precise valve gate systems, electric needle actuation and compact design to create a new dimension in performance and precision for demanding medical applications.

For more information please click here:

09.2021: Welcome to the KEBO Team!

Shortage of skilled workers especially in the technical professions, probably an issue for many Swiss companies...

Since 4 weeks we have support. Our new 2nd year apprentices (toolmaker and design engineer) are with us in our company after completing their basic training at the WIBILEA training centre and are helping with our daily work! We look forward to their cooperation and wish them an exciting and successful apprenticeship!

04.2021: The first plastics trade fair in 2021!

The first plastics trade fair in 2021!

KEBO AG will take part in the first plastics trade fair in 2021. We are at the Swiss Pavilion of Switzerland Global Enterprise, together with three other Swiss companies. Our employee in China, Mrs. Echo Xu, is looking forward to many visits!

Hall 10, Stand No. 10K41

11.2020: Something to celebrate!

Major milestone work anniversaries for three KEBO colleagues. A BIG thank you to them for their loyalty of service!

Hasan Tuzun (15 Years, Head of New Mould Assembly)

Hugo Filipe Filippe (5 Years, Spark Erosion)

Franco Frontino (20 years, Grinding Department)

Pictured here with Daniel Bodenmann C.F.O. (Left) and Gerold Keller C.E.O (right) All observing social distancing.

10.2020: We are upgrading!

KEBO AG received the formal handover of a new Sumitomo Demag Intelect s 180-700 machine for it's Technical Centre in Neuhausen am Rheinfall Switzerland.

The machine will be used for many tasks, primarily to run the range of Evolution Product Development Moulds it offers for material trials and fast track product development, along with customer mould validation and training.

KEBO enjoys a great relationship both with Sumitomo (SHI) Demag - Spritzgießmaschinen & their agent Mapag Maschinen AG in Switzerland.

09.2020: Finally an exhibition to talk about!

MedTec China started yesterday and runs from September 14–16th in Shanghai world Expo exhibition & convention center. Our Sales Manager for China Mrs. Echo Xu will be delighted to meet customers and partners in person. We are proud to share our booth with our strategic partner Kahle Automation at this important event.

Booth Number 2R110

05.2020: Employees in focus

Another employee celebrates his 25th year of employment at KEBO AG. W. Bigalke receives a gift from the two owners of KEBO Gerold Keller & Daniel Bodenmann.

Loyalty has a high personal value here at KEBO.

Photo left to right:

Keller – Bigalke – Bodenmann

04.2020: Cumulative KEBO experience

The 1st April marks a significant day for three valuable employees at KEBO.

B. Winet celebrates his 10th year, U. Schwarzer and S. Li Rosi an amazing 30 years with the company!

A huge thank you from the owners of KEBO Mr. Gerold Keller & Mr. Daniel Bodenmann for their dedicated service and loyalty.

Photo left to right:

Li Rosi – Keller – Winet – Schwarzer – Bodenmann

03.2020: Injection molds with highest longevity

KEBO Service Department completing third revision on a 10 year old mould that has completed 25,000,000 shots to date, ready to go again! Durability through design, quality of materials, precision manufacturing, skilled employees.

Simply mould making with passion from start to finish!

02.2020: Traditional KEBO Skiing weekend

A total of 20 employees took part in the annual KEBO ski weekend this year. With best slope conditions, fresh snow and a lot of sunshine two wonderful days were spent in Brand, Austria. KEBO's Teamwork is also encouraged outside of the daily work. Team building par excellence.

01.2020: Visit KEBO at MD&M West

Visit us!

We are exhibiting at MD&M West in Anaheim next month. Be sure to mark your calendars from 11-13 Februar

Find more information here at our event page. But first we are exhibiting also at Pharmapack Europe from 5-6 Februar in Paris

10.2019: K-2019: KEBO at Europe's biggest plastics exhibition

We are pleased to participate in the K-2019 trade fair. This with our own exhibition stand as part of Switzerland's joint presentation. You will find us in Hall 12 – on stand A51-01. We look forward to seeing you in Düsseldorf.

10.2019: KEBO AG 2019: A topic for 40 years

40 years of KEBO as a reliable partner whenever high-output injection moulds are needed. This fills us with joy and pride. In 2019 we celebrate this anniversary not only with our loyal fellow workers but, when the opportunity arises, like to clink glasses also with you, our dear customers and business partners.

11.2019: Record broken!

9 injection molding machines have never been seen in the premises of our testcenter. In addition to our four own machines, we are currently allowed to carry out FAT and validation processes on five customer machines. Thanks to our customers!