FORMULA FOR SUCCESS AND EFFICIENCY AT ITS BEST:

THE NEW MULTIVALVE VALVE GATE SYSTEM FROM KEBO

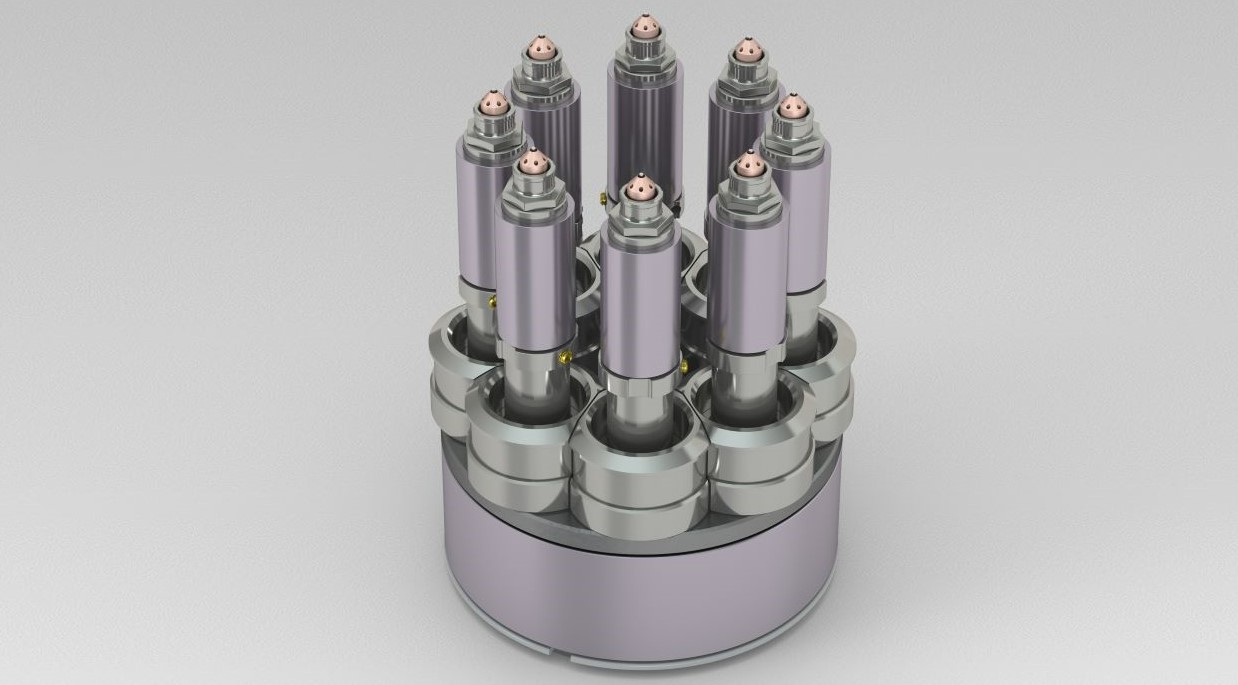

MultiValve – KEBO‘s new in-house development – combines precise valve gate systems, electric needle actuation and compact design to create a new dimension in performance and precision for demanding medical applications.

The ultra-compact system joins our „Evolution“ family of highly productive mould concepts and combines everything that makes KEBO moulds shine:

Large production volumes with a small footprint – thanks to high cavity density. Precise temperature control, low wear and high ease of maintenance - thanks

to our proven cluster design. With the uniqueness that every single needle can be individually deactivated. Challenge us with your task!

Megatrend Minituarisation

The trend in medical technology is moving towards ever smaller part geometries and article weights with critical tolerances and a high degree of complexity. After the injection moulding process, the majority of articles are sent to assembly units, where several injection moulded parts are assembled together. Here, possible defects in the final component are multiplied.

Thanks to KEBO's many years of experience in the field of valve gates, the existing know-how could be adapted to the needs of medical customers. The new development MultiValve stands out with the following advantages:

- first-class sprue quality

- high production volumes due to compact cluster design (pitch circle ø 60 mm)

- compact mould size (for the smallest possible injection moulding machines)

- long service life

- high ease of maintenance

The unique concept was implemented with the proven KEBO cluster design. Here, the development team succeeded in maintaining the space requirement of the existing open, compact cluster arrangement for the needle shut-off. The very small cavity distances enable maximum part output in relation to the mould area. The highest configuration level with 8 cavities per cluster will be shown at the fair - 4 or 6 cavities are also possible (depending on the part geometry and the gating position). Another unique feature is the ability to shut off individual cavities easily and safely.

Electric needle actuation

The medical market prefers fully electric solutions, especially for clean rooms. KEBO follows this trend and actuates the valve gate nozzles via an electric plate - with the following benefits:

- high precision

- high repeatability

- less wear and tear

- very clean (clean room)

- high process reliability

- Needle speed individually adjustable

- very good temperature control

Alternatively, the drive is pneumatically actuated.

KEBO PILOT MOULDS – INSERTS AND MATERIAL TESTS

So that we can respond promptly to customer requests, material tests, further developments and rapid sample production requirements, KEBO AG uses four in-house sample moulds. As only inserts need to be manufactured in existing mould bases, the total project time frame is reduced to a minimum.

Material tests, design optimisation, gate quality, functionality of assembly parts, dimensional accuracy, steel dimensions for subsequent production moulds and the shortening of validation phases represent a crucial cost advantage for our customers.

You want to find out what our MultiValve system can do for your requirement? We are at your disposal for an initial consultation.

The KEBO formula for success: