There are no compromises in our medical applications

In injection moulding technology, for medical products, tight tolerances, meticulous work methods and uncompromising validation processes are all synonymous. Our company has been consistently implementing these requirements, norms and standards every day for decades. We offer our customers efficiency, cost-effectiveness, strict adherence to individual and market demands, excellent optics and long tool life with minimum maintenance.

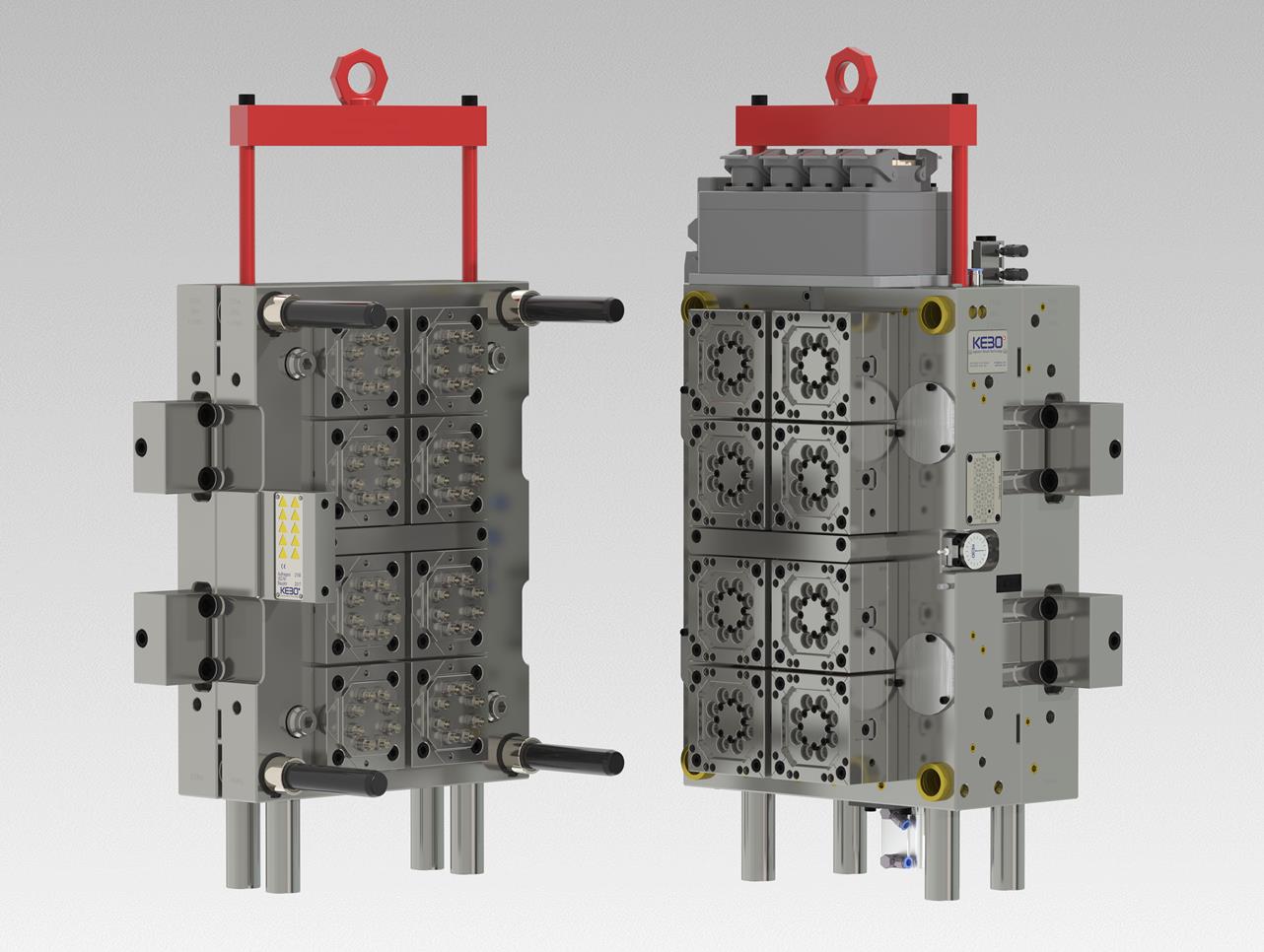

Profitability is increased through the high number of cavities and the very short cycle times. Stack mould technology enables high output in the smallest of spaces.

Our hot runner systems deliver high quality, from 2 to 8 cavities per cluster. We achieve the best possible gate quality and dimensional stability.

The long life of our moulds is the result of our high-precision processes. This means that wear and tear are minimised. Our products need very little maintenance, even in large-scale production processes, and remain failure-free over many years.

We have the in-depth expertise to guide our customers through the appropriate validation processes and assist them in obtaining the required certifications.

Typical products include:

- Infusion and transfusion parts

- Injection systems

- Connectors

- Syringes

- Blood collection products

Standards lead to reliability and reduced risks

In the last years we have established clearly defined standards in Medical Applications. For many of these medical mouldings we rely on well-proven design standards which permit us, thanks to optimally laid out hotrunner systems, to achieve the maximum productivity of your plant and equipment.

Whether 16, 32 or up to 144 cavities – in one plane or on two tiers: A maximum quality of your plastic parts and especially also of the gate, top surface quality and fast cycles are the result of a perfect interaction between hotrunner and mould.

Ever since the nineteen-eighties, KEBO AG has been using its own fully-heated hotrunner technique for Medical Applications, also where stack-moulds are concerned. The service-friendly and modular design of the cluster principle allows to take optimal advantage of the space available in your injection moulding machine, thereby optimizing the economic efficiency of your entire production system.

KEBO AG has four own test moulds (of pre-series execution), two of which with fully heated hotrunners for side-gating. Seeing that only the inserts for existing impressions need to be made, weak spots can be detected and dealt with at an early stage and quickly.

We are familiar and experienced with different concepts for the lying arrangement „lift & strip“, side-gating with unscrewing or the use of electric servo-motors for unscrewing or gate-pin actuation.