The highest quality with the fastest return on investment

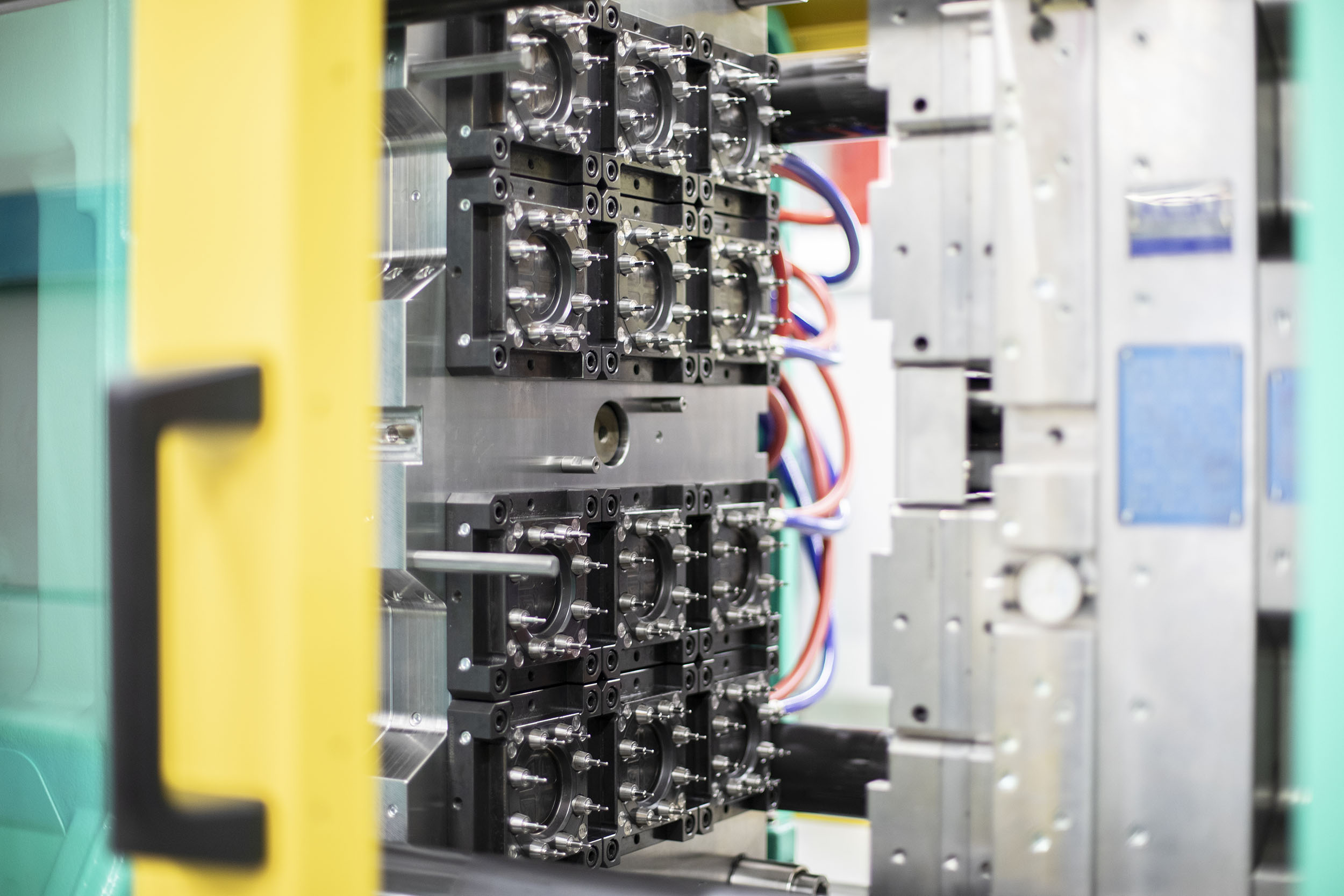

We specialise in injection moulds to meet demanding customer requirements. We offer very short cycle times, even with a high number of cavities.

Our development team looks back on 40 years of experience and works with the latest technologies. Through close contact with the major industry players, we engage in international knowledge transfer.

Our engineers start with a customer idea and develop this into a finished tool. To do this they use state-of-the-art equipment and their outstanding initiative.

In Neuhausen, Switzerland we produce products that are in demand all over the world. Our in-house production, high degree of vertical integration, state-of-the-art equipment and flat management structure guarantee reliable profitability for customers over the long term.

Our in-house technical centre carries out comprehensive tool tests, which are all fully documented. Additionally, we also support our customers in validation processes.

The longevity of our tools and our maintenance service (which we also offer for third-party products) are highly appreciated by our customers.

The best chance for your products success: Our know how.

Medical

Know how in the sophisticated design of medical products. >

PHARMA / LABOR

High-Performance for Pharmaceutical and Laboratory Devices. >

Thinwall / IML

Balanced fill of the cavities, thinnest wall sections and high output. >

INNOVATION. IN ALL PARTS

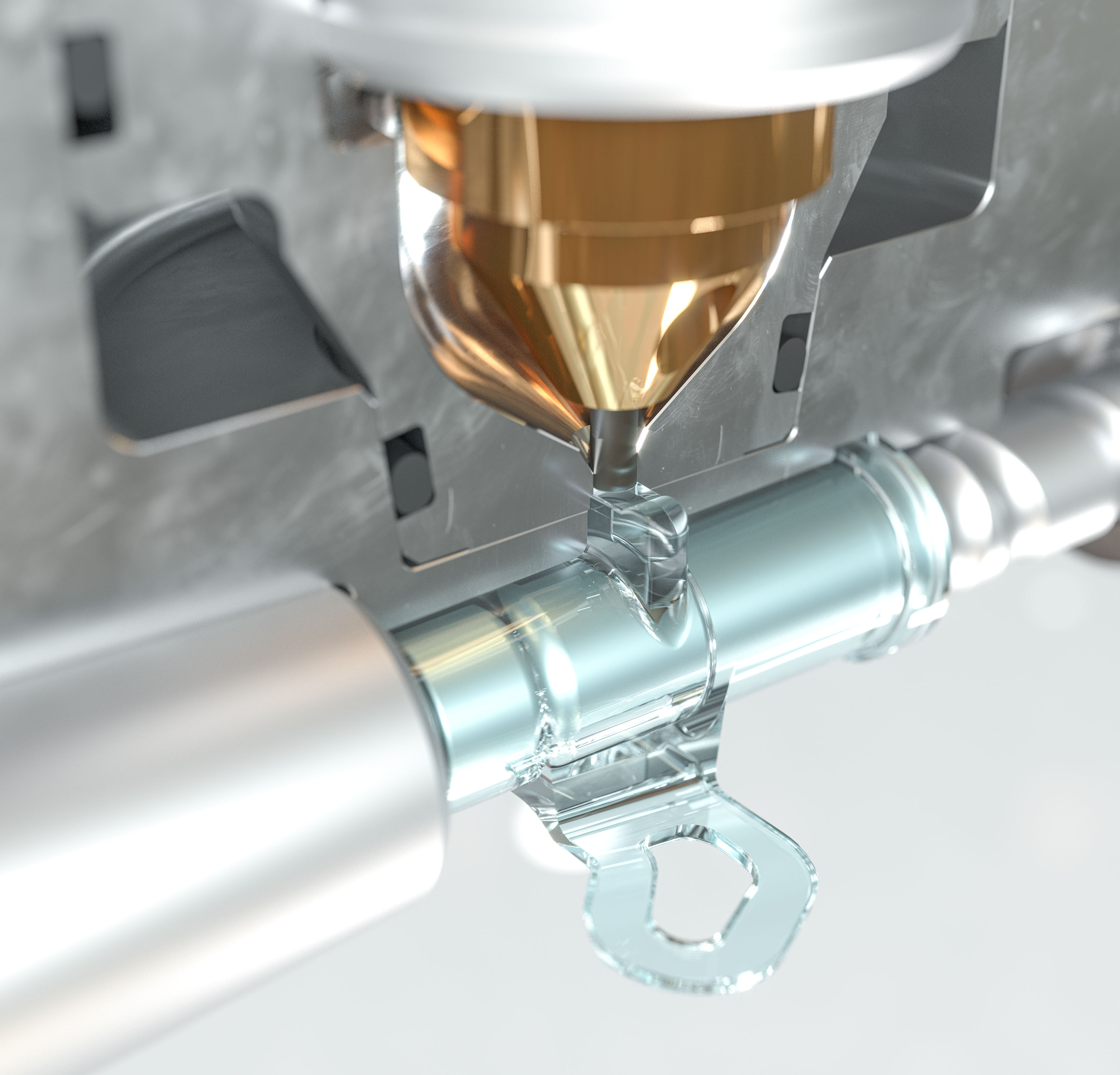

Hotrunner technology with side-gating:

Our own innovation is highly appreciated wherever surface quality, processing of demanding plastic materials and large numbers of cavities are of importance.

- Stable heat circumstances

- 2-8 gating points per cluster

- Outstandingly good flow characteristics

Test moulds for pilot projects:

Prospects are one aspect – feasibility another. In complex issues we start on a small scale before going ahead full steam. A test mould allows us to detect production problems that are easier to cope with in the run-up.

- Hotrunner applications, EcoTip, MultiTip, MultiValve and star nozzle

- 2-16 cavities

- Short implementation times

If you have a project, let's look at it together. We are always open to new challenges and available to you at any time. We look forward to your contact.