Only extreme precision allows for the thinnest walls

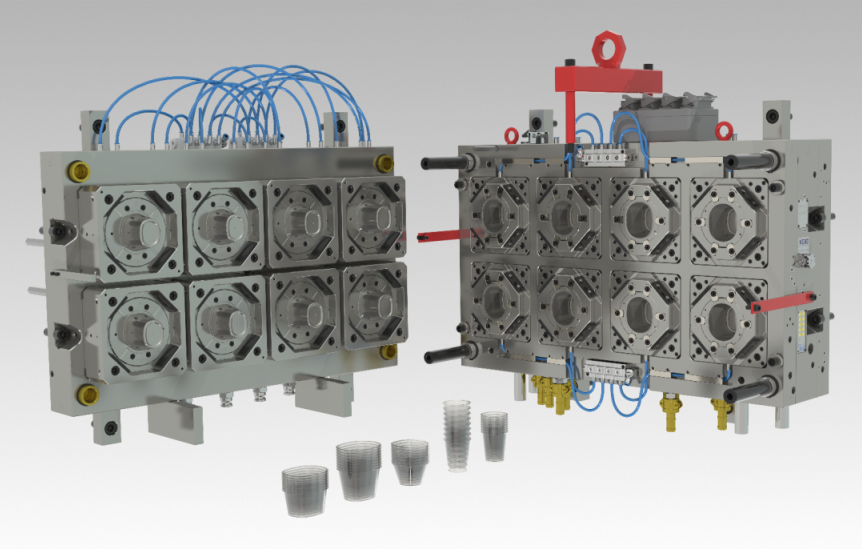

In thin-wall applications and in-mould labelling (IML), a specialist can recognise the quality of the injection mould by its high precision finish, constant process temperature control, excellent material filling capability achieved by an impressive hot runner system.

Above all, our moulds prove themselves in production – because they are fast, highly reliable and produce consistent results over the long term. This precision is not only the crucial factor that provides for almost maintenance-free operation and low wear. The perfect interaction of materials, machinery, tools and process control is also a key requirement for material savings – because optimised thin-wall injection moulding processes typically use less plastic.

Particularly in the packaging sector, our customers are impressed by our expertise in thin-wall injection moulding and in-mould labelling, not least because the cycle times and cavities that we achieve and our experience in stack mould technology are available for all to see.

Typical products include:

• Round or square margarine, cream cheese and yoghurt cups

• IML packaging

• Pots with handles

• Airline cups, drinking glasses

• Lids for food containers

The safety of standards

Over the last years our company has established clearly defined standards in the fields of thin-wall applications and in-mould-labelling (IML). When packaging parts are concerned, we rely on our well-proven design standards which permit us – thanks to optimally laid out hotrunners – to achieve the maximum productivity of your system.

Whether 4, 6, 8 or 12 cavities, in one plane or on two tiers: Thinnest walls are the result of a perfect interaction between the components hotrunner, mould, injection moulding machine and automation.

In the four decades of our existence we have manufactured more than 500 moulds just for thin-wall applications. We designed our first mould incorporating IML already in 1985.

We know exactly what matters and take advantage of moulding machine and automation capacities right to the limits of what is physically possible.

OVER 40 YEARS OF EXPERIENCE IN THIN-WALL PACKAGING

KEBO AG has been building tools for thin-wall packaging since 1980. KEBO AG is one of the pioneers in IML technology, the first IML system was realised in 1986 with the company Oscar Beck AG (today Beck Automation AG). Of course, the technology in the thin-wall and IML sector has developed further over the past decades.